- Bespoke Shoes Unlaced - The Journal

- Posts

- Journal : Issue 10 : Part II - Craft of Shoemaking Award 2025

Journal : Issue 10 : Part II - Craft of Shoemaking Award 2025

A glimpse into our shoemaking world

JOURNAL: ISSUE 10

Top row left to right: handsewn and beaded moccasins by Emma Treleaven, weightlifting shoes by Daniel Cope, walking boots by Jamie O’Grady, Wellington boots by Ross Edwin Bell. Bottom row left to right: 1st placed ‘Misfits’ Derby boots by Caleb Smyth, 2nd placed heart Derby boots by Elizabeth Dugmore, deconstructed Brog boots by Richard Fitzpatrick, 3rd placed button boots by Zachariah Webb. Photos by Mark Witter

PART II -

2025 CRAFT OF SHOEMAKING AWARD

(CoSA)

PART II

In Part I of the Craft of Shoemaking Awards we looked in detail at the boots that took first, second and third place. Part II takes a deep dive into the five finalists who brought such strong competition to this, the inaugural award.

Daniel Cope

Daniel Cope with his weightlifting shoes - a blend of form and function in the style of the classic 1980’s shoes.

Dan is apprenticed at Church’s, but as a weightlifter, he is on a mission to develop a comfortable, repairable, weightlifting shoe.

He finds most weightlifting shoes are too narrow, and whilst ASICS 727’s have a good, wide fit and can be repaired the outsole stitches are prone to breakage.

In response, Dan’s design has an unstructured toe cap, to allow for more flexibility, freedom of movement in the toes and to reduce weight. It has a hand-stitched midsole, cemented rubber outsole and a separate heel unit so that they can be repaired without impacting the uppers.

COMPONENTS

Both the insoles and midsoles were made up of a 5-iron oak bark tanned leather provided by Church’s. This is about half the thickness of the insoles used for hand welting, but perfect for more flexible weightlifting shoes.

The heel stiffeners and shanks were made from a 4-iron oak bark tanned leather, again provided by Church’s.

The sole was in a 1.8mm, hard-wearing rubber outsole. The sock lining was made of a 3- 4mm chip foam with a thin black veg tan leather over the top.

LASTS

Under the careful guidance of Sonny at Spring Line, (including taking Dan’s measures) Dan sourced a pair of lasts that would be a good fit for his feet.

Clockwise from top left: Dan’s choice of last; the design drawn onto the last; the quarters and heel counter stitched together; a prototype of the design to test the pattern; skiving the leather

UPPERS

The uppers were made of Black Desert Oasis suede, from English tannery, Charles F. Stead, 1.8-2mm thick with a rugged nap and contrasted with a thin white leather lining supplied by Church’s. The inside of the shoe is lined with fabric, increasing breathability and reducing weight where possible and the tongue and collar were padded with 10mm foam.

The upper design is lace-to-toe, trainer style. It includes a ‘V’ pattern on the quarters and a hand- stitched ‘D’ on the facings, in homage to Church’s and their popular ‘Shannon’ shoes. Dan developed and adjusted his patterns with support from Bruce Moore at Church’s

He used the patterns to cut well fitting heel stiffeners which he molded on the last and to hand click the upper pattern sections from the suede, white leather and fabric liner.

Dan has had limited experience of closing as part of his apprenticeship, so this was one of the more challenging steps for him. He closed his uppers on a Global Post-bed machine, stitching 12spi and a contrasting white thread with the black. He padded the tongue and collar; hand punched a pattern of 1mm holes in the toecap, machine stitched the ‘V’ design in place; saddle stitched the D’s in place with 1mm black waxed thread; and hand punched the eyelets .

The upper lasted over and nailed in place; matching the uppers; a simple leather shank for support

MAKING

Dan blocked his insoles using the Japanese method of binding them (he used crepe bandage rather than the more commonly used rubber inner tube). Once dry they were trimmed to shape and he then hand-lasted his uppers, cementing them to the insole once they were tight to the last. They were left to dry before the nails were removed and the underside was skived smooth.

Dan used a leather shank for flexibility and filled the forepart with cork, all skived and rasped smooth before cementing a midsole in place. A sole press was used to make sure it was attached securely, before it was trimmed by Keith Brady at Church’s. Dan punched a row of stitch holes 15mm in from the edge using a pegging awl and a hammer, aiming for 3 stitches per inch, and then stitched the midsole in place.

Hand stitching the sole; the soles and heels ready for finishing

He used two different techniques to stitch the midsole, George Koleff’s technique of ‘Inside Sewing’ and a lockstitch technique, both difficult but with the latter proving a little quicker and then cemented a rand (welt) to the midsole. The heels were built to the modern height for weight lifting shoes of 0.75” and then cemented to the soles. Dan called on Keith again to trim and sand the heels and sole edges.

The lasts were pulled, edges finished with a natural edge ink and the heels secured with nails from inside the shoe. Dan sourced recycled chip foam to make the footbed and then covered it in black leather for comfort and to coordinate with the upper.

Follow @lower.case.dan

Ross Edwin Bell

Ross holding his hand craft Wellington boot at the awards, wearing them and with man’s best friend, the finished Wellingtons on the work bench

Ross is a highly skilled, self-taught leather craftsman based in Norfolk.

For the award, he challenged himself with making a pair of Wellington boots suitable for working, walking and riding and named ‘Copenhagen’ after the Duke of Wellington’s favourite horse.

LASTS

Ross chose an elegant shaped last with a cupped heel to alleviate the weight of the body when standing and walking all day and generous room at the toe for comfort.

UPPERS

The uppers are made in oiled nubuck, chosen because it is water resistant, durable and easy to maintain, not showing the scuffs and scratches that regularly occur from use. The lining is a natural undyed vegetable tanned calf skin for maximum breathability for the foot, to not discolour socks and to guard against any allergic reactions that can occur from chrome tanned leathers. The inlay is made from horse hair fabric.

Clockwise from top left: Letters being clicked from the boot leg, finished boot legs, words hand stitched on boot legs, underlay letters stitched in place,

The decorative stitching on the boot uppers was all done by hand using a waxed linen thread at a stitch count of 12spi.

Vamp being blocked or crimped to take the curve at the front of the leg

MAKING

The insoles and soles were made from oak bark tanned leather which leads to a lighter, more water resistant leather whilst still being incredibly hardwearing. The toe puffs and counters were also cut from vegetable tanned leather and stiffened with natural paste glue and the sole was filled with 100% natural wool felt for comfort and durability.

Clockwise from top left: Insoles blocked with bands, welting, sole stitching, finished heels and sole, toe puffs drying

Ross made the boots entirely by hand - bar using a bells skive - hand lasting, welting, sole stitching and building and finishing the heels, resulting in a truly original pair of handsewn, inlaid and saddle stitched Wellington boots.

Follow @edwinbelldesign

Richard Fitzpatrick

Clockwise from top left: Richard holding his finished brogue at the awards ceremony, the boots and their bespoke wooden box, the finished boots, boxed and on display

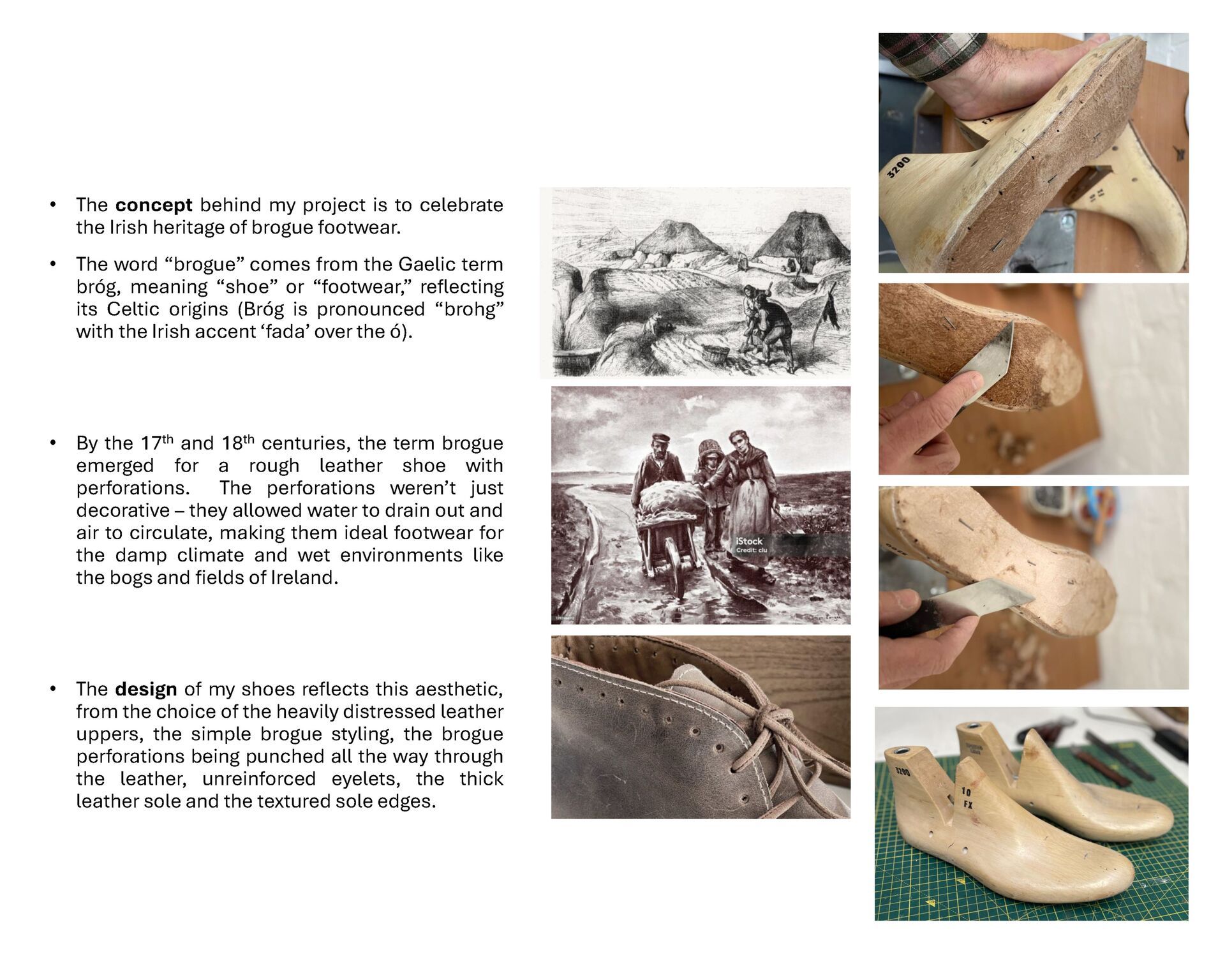

Richard’s boots celebrate the Irish heritage of brogue footwear. By the 17th and 18th centuries, the term brogue was being used to describe a rough leather shoe with perforations. The perforations weren’t just decorative, but were designed to let water out and air to circulate, ideal for the damp climate and environment of the bogs and fields of Ireland.

The history of the brogue and concept behind Richard’s design

LASTS

The brogue boots are made on a boot last with a medium/high toe spring and steep cone.

UPPERS

Starting with a Chukka boot pattern, Richard experimented with various punch patterns and their positioning, using a test upper to refine the brogue pattern. To maintain the natural aesthetic, he opted for plain eyelets punched through the leather without any metal or blind eyelets.

Developing the pattern from the last, punching the brogue pattern, choosing laces, closing the uppers, skiving seams

Careful positioning of the brogue punch pattern, joining the lining quarters and vamp, pulled over, the uppers pulled over the lasts, punching holes

MAKING

The boots were lasted with leather toe puffs and stiffeners, a midsole was cemented on, the sole was blake stitched in place and then the heel was built from layers of leather including the top piece to keep the natural aesthetic. Then the soles and heels were finished by hand.

Follow @fitzpatrick7165

Jamie O’Grady

Jamie with his boots at the awards; the finished boots; smooth finished leather soles and heels; the boots in nature.

Jamie graduated from the BA Footwear Design degree at De Montfort University this summer. He’s been drawing and creating from a young age and through various studies including fine art, graphic and product design - has developed a deep admiration for functional and beautiful design.

Jamie’s design concepts, colourway, drawn up last and mean forme

Jamie developed a pair of bespoke walking boots for a specific client, starting with careful selection of the right type of last for a good fit. He modified the chosen last to suit the boot design and client aesthetics and fit.

Jamie’s leather selection and pattern lay; choosing a last to suit the client’s fit and style

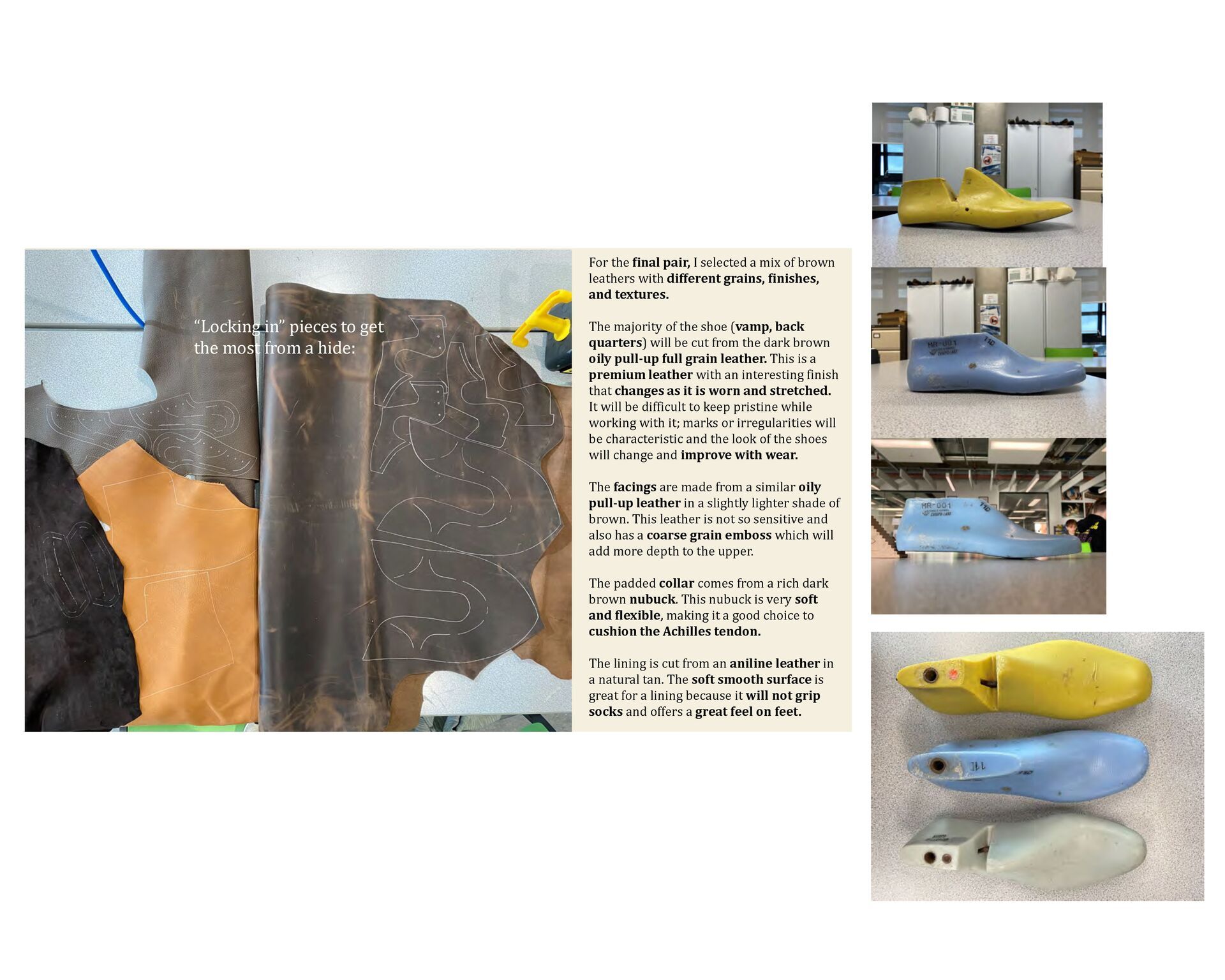

He refined his boot design to give a more formal look to a traditonal walking boot, drawing it onto the last to develop good proportions befoe making his pattern pieces. Jamie created a number of different mock-ups to refine and improve the original concept before finalising his choice of leathers. They were selected for their performance and look - a mix of oily pull-up leather, embossed grain and soft nubuck.

Clockwise from top left; some of Jamie’s detailed storyboards showing the clicking and closing process; lasting the uppers; blocking the tongues and stitching the uppers

The finished boots have blocked tongues for comfort, oak bark leather components, a decorative rand and natural polish finish.

Follow @jogfootwear

Emma Treleaven

Clockwise from top left: Emma with her finished moccasins at the awards; moccasins and portfolio of making; finished fur-lined moccasins

Emma is a curator, maker and academic, working on a practice-led Ph.D about women shoemakers working in London between 1850 and 1914. She is the Collections Manager at Amersham Museum. Emma made a pair of moccasins for the competition, hand stitched at home as she looked after her baby daughter.

Clockwise from top left: Tool kit for hand sewing at home; moccasin apron clamped in place ready for pleating; hand beaded apron and quarters; uppers and linings; hand beaded floral design

Since Emma made her first pair of shoes in 2019, shoemaking has remained her primary focus of interest and is heavily influenced by her historical research. She enjoys unearthing rare shoemaking and decorative techniques from historical sources, like beading and lace making, and incorporating them into her shoemaking.

Hand beaded apron and stitched in place - outside view; hand beaded apron stitched in place, inside view; lining clamped in place with fur cuff

Emma grew up in western Canada and has always been interested in the intangible and tangible cultural heritage of First Nations cultures.

Her interest in moccasin making and its traditions began as an exploration of the differences in construction of First Nation and European footwear.

A love of flowers drew her to Métis beadwork, which inspired the choice of decoration for her moccasins.

Fur cuff hand stitched in place - rear and front views; finished fur cuff

Follow @emmatreleaven

2026 Craft of Shoemaking Award

CALLING ALL SUPPORTERS

We sat down with the Cordwainers last month to start planning next year’s award. we’d love to see the award continue to grow, so please get in touch, if you would like to get involved. We’re seeking financial sponsors for prize and makers and manufacturers to get involved by donating your time and expertise to offer mentoring or training.

2026 ENTRANTS - REGISTER YOUR INTEREST

If you would like to enter the award next year, please email us at [email protected] so that we can add you to the mailing list to keep you up to date.

Craft of Shoemaking Award - Winners Exhibition

If you’d like to see what the competition looks like then please come along to Oxo Tower during the London Design Festival. We’re proud to be showcasing the top three award winning pairs of boots by Caleb Smyth, Elizabeth Dugmore and Zachariah Webb, along with their portfolios showing the making process.

Opening Times:

Saturday 13th and 20th September: 11 - 5pm

Monday to Thursday 15th - 18th September: 10am - 5pm

Venue: Carréducker, Unit 1.20, Oxo Tower Wharf, Barge House Street, London SE1 9PH

In the meantime, if you know someone who would enjoy The Journal please copy and share the link below with them.

Deborah & James