- Bespoke Shoes Unlaced - The Journal

- Posts

- The Journal Issue 1 - Welcome

The Journal Issue 1 - Welcome

A monthly glimpse into our shoemaking world

THE JOURNAL - ISSUE 1

BESPOKE SHOES UNLACED

We first shared a glimpse of our lives as shoemakers and of the craft of handsewn shoemaking back in 2006, when we launched our weekly shoemaking blog.

This was at a time when few shoemakers were sharing their knowledge and there was no social media to speak of. The blog’s simple, photo-essay format proved popular and the archive on our website, still provides a useful resource for thousands of aspiring shoemakers around the world.

As we celebrate our 20th year, we thought it would be fun to take a deeper dive into life in the workshop - the shoes we love and our favourite tools, techniques and leathers - with a monthly journal.

This is the first issue, to give you a flavour. We hope that you enjoy it and if you’d like to continue to receive monthly news from the workshop, please subscribe below.

Many thanks

Deborah & James

Deborah & James

10 THINGS YOU MAY NOT KNOW ABOUT US

2004 - 2024, Carreducker is 20 years old

We’re not a couple

We changed careers to become handsewn shoemakers

We’re proud to be Freeman of the Worshipful Company of Cordwainers

We love teaching shoemaking

We hate Crocs and Uggs

We listen to BBC 6 music in the workshop

We have taught people from all over the world, from as far afield as Australia, Argentina and Alaska

James is vegetarian and Deborah is from the tiny Channel Island of Sark

The leathers we use are by-products of the meat and dairy industry and are tanned using natural organic bark and vegetable matter.

BESPOKE SHOE of the month

We’re going to focus on a favourite pair of our handsewn shoes every month, looking at the shape, style, leathers and construction.

Chester Oxford

CHESTER OXFORD

SHAPE

The Chester Oxford is made on a copy of an original 1930s last (the original was very pitted with woodworm and from use).

It is slim, with an elegant forepart, ‘snub’ toe

and a deep toe box.

STYLE

This is a classic Oxford pattern with five pairs of eyelets.

Classic Oxford style lines

The vamp seam sits straight across the facings and gently curves back towards the heel and is closed with a double row of stitches.

A leather semicircle tab conceals the stay stitch at the base of the facings.

There is a line of yellow slip beading (piping) between the lining and the upper. This is usually the same colour as the upper but we wanted the pop of colour along the facings.

A decorative 1mm brogue punch pattern traces the topline and down the front of the facings and is underlayed with yellow kid

Single brogue punch pattern

LEATHER

The leather is Cordovan (horse) from Claytons (now known as Spire Leather) a small artisan tannery in Chesterfield in the north of England.

The patterning across the skin varies and the quarters were cut to show off the beautiful, natural patterning.

Natural patterning on the skin

The quarters are lined with glace kid and the vamps in natural vegetable tanned russett for its strength and moisture wicking abilities.

Yellow kid used as a contrast lining, piped top line and beneath brogue pattern

MAKING

All of our handsewn shoes are made using Bakers of Colyton oak bark leather components from stiffeners and toe puffs to heel lifts.

The Chester is made with a light ¼” sole, hand stitched 12 stitches to the inch, a bevelled waist and a 1” stacked leather heel. It is finished with a dark brown dye and matching wax, burnished into the sole and edges.

For the man who is truly good and wise, we think, bears all the chances of life becomingly and always makes the best of circumstances…as a good shoemaker makes the best shoes out of the hides that are given him, and so with all other craftsmen

On the bench

We always have a wide variety of work on the go at any one time. Some shoemaking is straightforward, but some is a little more complicated. We thought it might be helpful to share what we do for a specific challenge, as a work-around or to get out of a jam!

Cork Lift

Cork lift molded to the last with the insole attached, ready to be trimmed

If you have a disparity in leg length or are making for someone who has, a cork lift is a great way to make the adjustment discretely and without adding extra weight to the shoe or boot.

It’s also a great way to add a little extra height, just ask Messrs Cruise, Radcliffe and Downey Jnr.

We had a look through our blog archives and found this post from 2012 that describes how to create a cork lift.

Remember that you’ll also need to add extra lasting allowance to the upper. If they’re bespoke, then the design should be carefully adjusted to disguise the added height.

Tool Tips

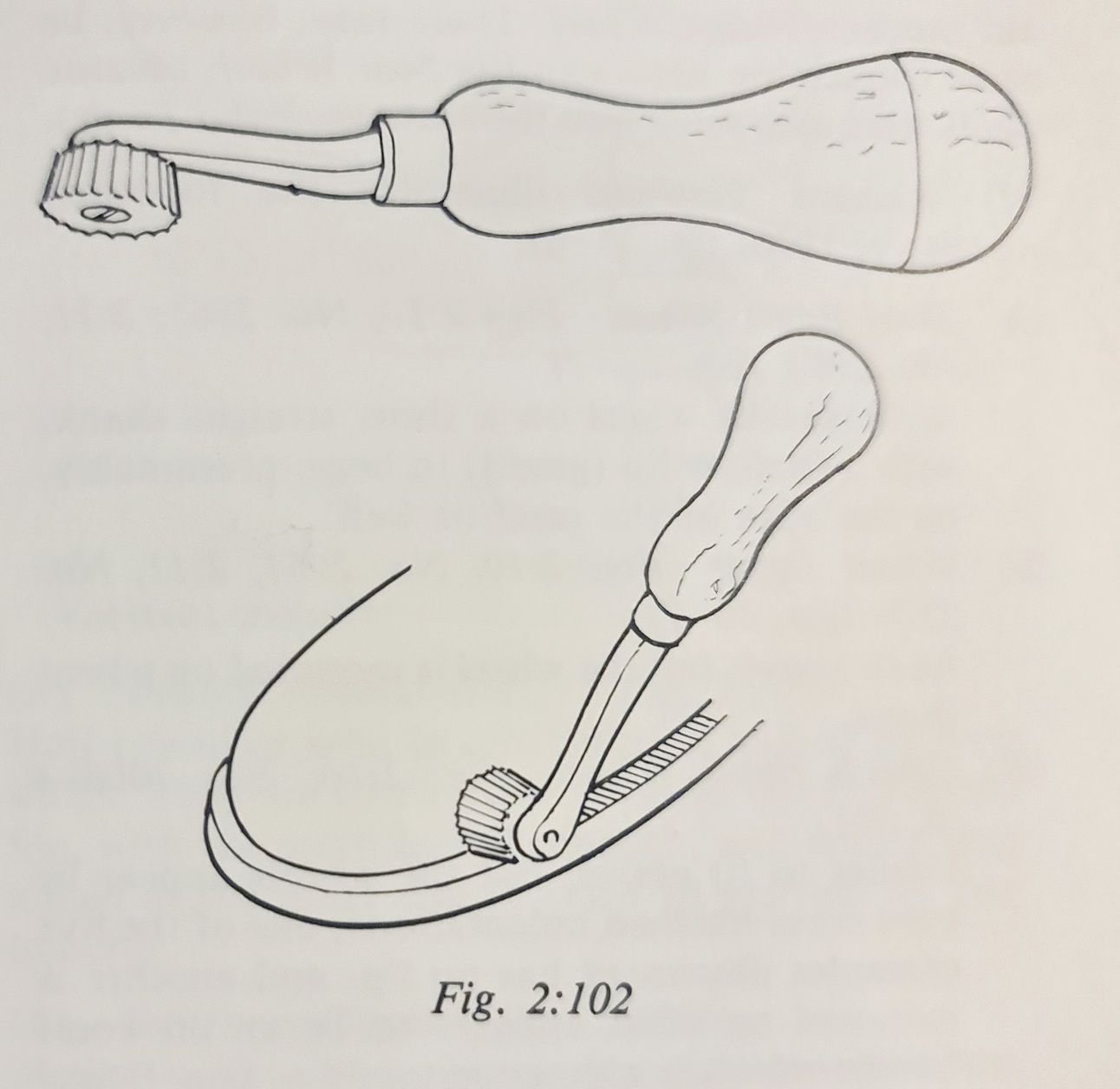

Fudge Wheel

Credit: Dictionary of Leatherworking Tools | What is a fudge wheel? The fudge wheel is designed to space the sole stitching evenly and, once stitched to help tighten and neaten the stitches. The wheel is in the shape of a cylinder or cone with a serrated surface, set on a steeel shank and with a turned wooden handle. The width of the teeth on the wheel varies from 6spi (stitches per inch) to 24spi. Why is it called a fudge wheel? Who knows, but maybe because it is because it can be used to fudge or fake the welt so it looks stitched. Where is it used? The cone shape allows the wheel to run right next to the upper without damaging it (as long as it is not too hot). How does it work? The wheel is warmed in a burner and pushed down onto the surface of the welt in pushed forward around the shoe. Take a look here to see the fudge wheel in action. |

…the real stitching will appear regular if the awl is put through exactly in the wheel marks.

As the stitch is wanted to show up boldly on the welt, the fudge wheel should be run around it before stitching is commenced

Shopping

OFFER - 10% discount on vintage tools

Code: Oldies are the best

If you’d like to hear more from the workshop, please subscribe to the journal below.

We promise it’ll only be once a month, we won’t share your details with anyone and we’ll try to make sure that there’s something of interest for you in every issue, whether it’s new shoes, tools, materials, events or projects.

And if there’s something you’d like us to include, please email us with your suggestions [email protected]…what would you like to hear about?

Many thanks for joining us for the first issue

Deborah & James